Develop automatic disc changing technology to optimize the milling process, without personnel on duty, 24 hours uninterrupted work. The D52-ADC becomes the dental laboratory of choice with higher work efficiency and less manual input, taking your dental laboratory to the next level in terms of digital workflow.

Automatic Disc Change

D52-ADC has undergone tens of thousands of fatigue tests by technicians, and the success rate of automatic disc change is as high as 99.5%. There is no need for manual participation in the whole disc changing process. After the scanning probe automatically recognizes the material disc information, it uses the simplest path to change the disc, reducing the occurrence of faults, so as to reduce the cost of labor and equipment maintenance at the same time.

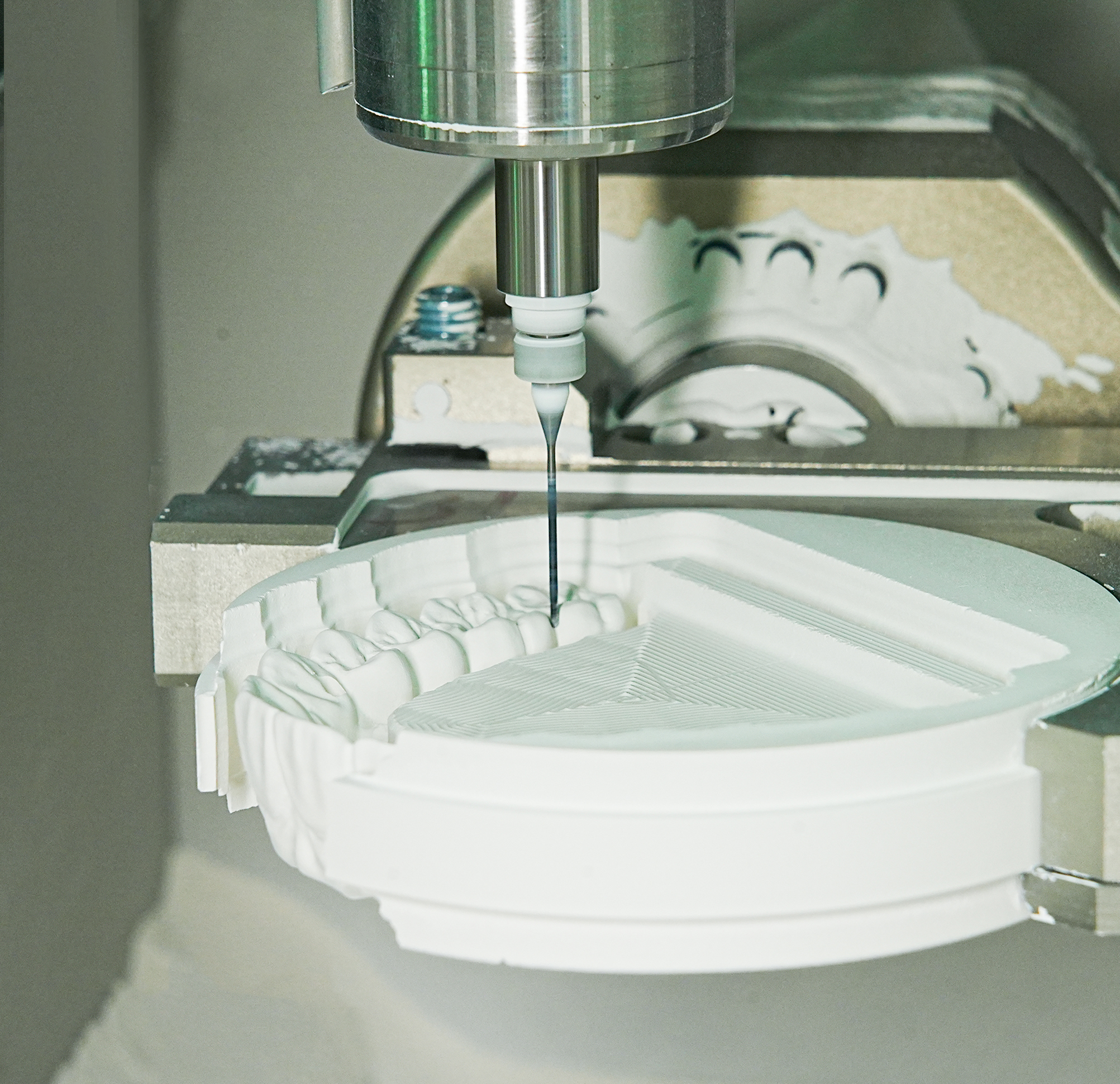

Strong Spindle

As the core component of a milling machine, the spindle is just like the engine of a car. A good engine will make the equipment have lower energy consumption and stronger power. The new upgrade of D52-ADC, the spindle power from 500W to 1800W, the high-power spindle allows the equipment to play a more stable role in the milling of various materials, driving the equipment to work efficiently.

Want to be the first to know?

Subscribe to our monthly newsletter and never miss any news about products, promotions, blog posts, services and events!

* Will be used in accordance with our Privacy Policy.